Oulu Energy plans a 100 MW hydrogen plant in Oulu, Finland

Partner for the project planning is the Finnish company P2X Solutions, which is currently constructing a hydrogen production plant in Harjavalta, western Finland.

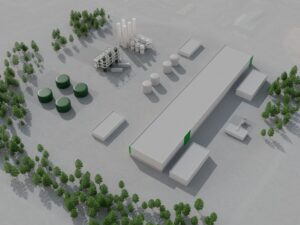

According to the preliminary plan, the whole project planned in Laanila industrial area, would include an electrolysis plant with a capacity of up to 100 MW, a carbon capture plant, a hydrogen and carbon dioxide storage, and a further processing plant whose final product could be methane or methanol, for example.

This will be Oulu Energy’s first hydrogen project and significant even on the scale of Europe.

The products created by the hydrogen plant could be used to replace fossil fuels in road, maritime and air transport.

According to the preliminary estimate, approximately 200–400 gigawatt hours (GWh) of heat energy per year would be created as a by-product, which could be transferred to the district heating network, while the oxygen could be recovered for industrial use.

“The heat energy gained would correspond to approximately 10–30% of Oulu’s annual district heating demand. This would enable us to produce heat in an environmentally friendly manner and improve the competitiveness of district heating,” said Kimmo Alatulkkila, development director at Oulu Energy.

“Oulu Energy is a pioneer in sustainable energy production in northern Finland. It is great to be able to advance a joint project that shows that green hydrogen can also be a solution for cutting emissions from heat production.

"When completed, the capacity of the Oulu hydrogen plant would be up to 100 megawatts, which makes it very significant also on the scale of Finland. For P2X Solutions, the project would mean a significant scaling up of operations from our facilities in Harjavalta and Joensuu,” said Herkko Plit, CEO of P2X Solutions.

In addition, the project aims to investigate the possibilities of recovering the biogenic flue gases from local industry and power plants in the further processing of hydrogen.

In the project development phase, the feasibility of the plant and location options are examined, and an impact assessment is carried out.

The investment decision is estimated to be made in autumn 2025, and the plant could be ready by 2028 at the earliest.